Thanks to our profound knowledge of process and foundry technology for aluminum and magnesium, acquired over more than 40 years, we achieved a high level of efficiency in design and construction of HP die casting moulds and deburring tools.

With steady investment in manpower and equipment we became a safe and reliable Partner for our customers in order to cope with the current market challenges.

We’re in condition nowadays to offer our customers a whole service package from design, simulation and construction, performed by four companies of our Group with approx. 75 employees, to first samplings and 2D-3D measurements of cast parts.

- Production process

- see page

- constantly updated machinery & equipment

Universal Stampi was founded in 1966, today it has a main plant with an overall area of 12.000 m2, 6.000 thereof m2 indoor area, where we perform all activities related with the manufacture of HPDC tools. The company is being run by some staff, highly experienced in the field of HPDC tools.

Nowadays we’re in condition to offer our customers a complete service package, with design, simulation and construction of HPDC moulds, by the four companies belonging to our group with a total of approx. 75 employees, down to first sampling of the tools and 2D-3D measurement of the cast parts.

we give shape to your ideas

Universal

Stampi

we give shape to your ideas

Universal

Stampi

Thanks to our profound knowledge of process and foundry technology for aluminum and magnesium, acquired over more than 40 years, we achieved a high level of efficiency in design and construction of HP die casting moulds and deburring tools.

With steady investment in manpower and equipment we became a safe and reliable Partner for our customers in order to cope with the current market challenges.

We’re in condition nowadays to offer our customers a whole service package from design, simulation and construction, performed by four companies of our Group with approx. 75 employees, to first samplings and 2D-3D measurements of cast parts.

- Production process

- see page

- constantly updated machinery & equipment

Universal Stampi was founded in 1966, today it has a main plant with an overall area of 12.000 m2, 6.000 thereof m2 indoor area, where we perform all activities related with the manufacture of HPDC tools. The company is being run by some staff, highly experienced in the field of HPDC tools.

Nowadays we’re in condition to offer our customers a complete service package, with design, simulation and construction of HPDC moulds, by the four companies belonging to our group with a total of approx. 75 employees, down to first sampling of the tools and 2D-3D measurement of the cast parts.

Markets

Markets of

Destination

90% of our products are destined to the automotive industry.

%

Italy

%

UE

%

Extra UE

Production

Our

Production

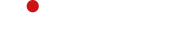

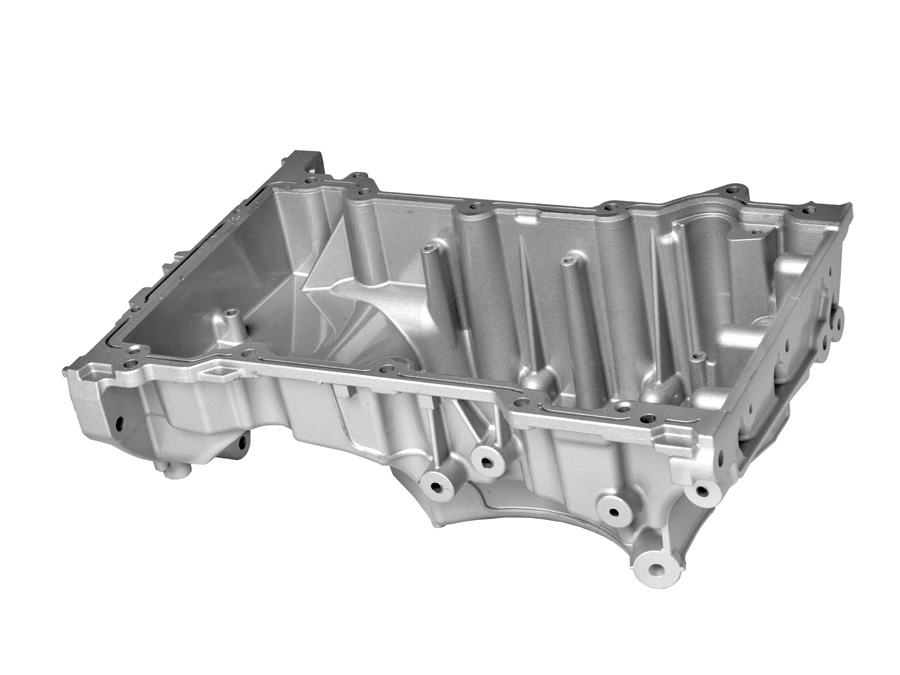

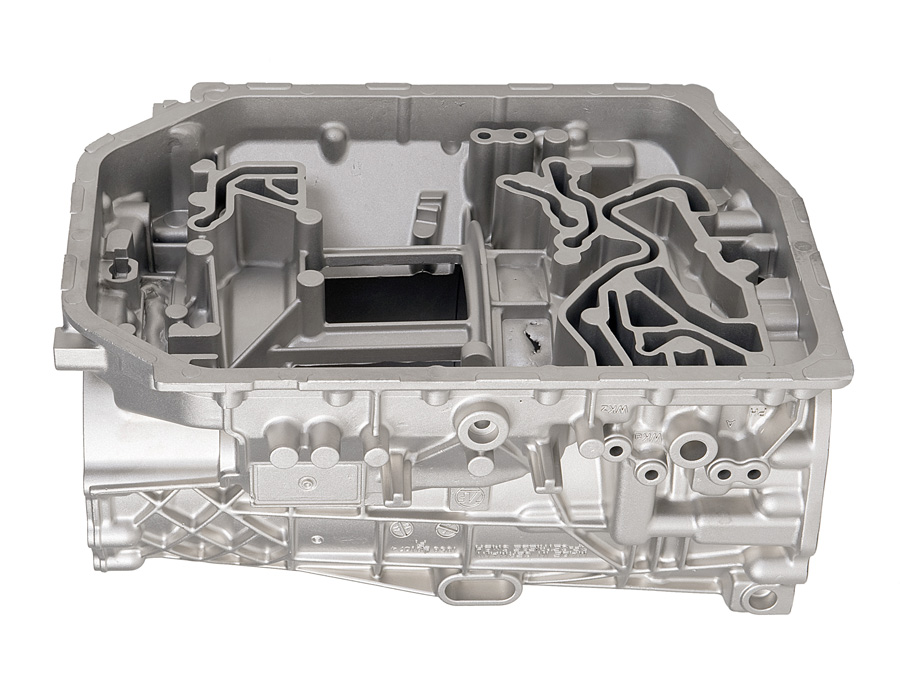

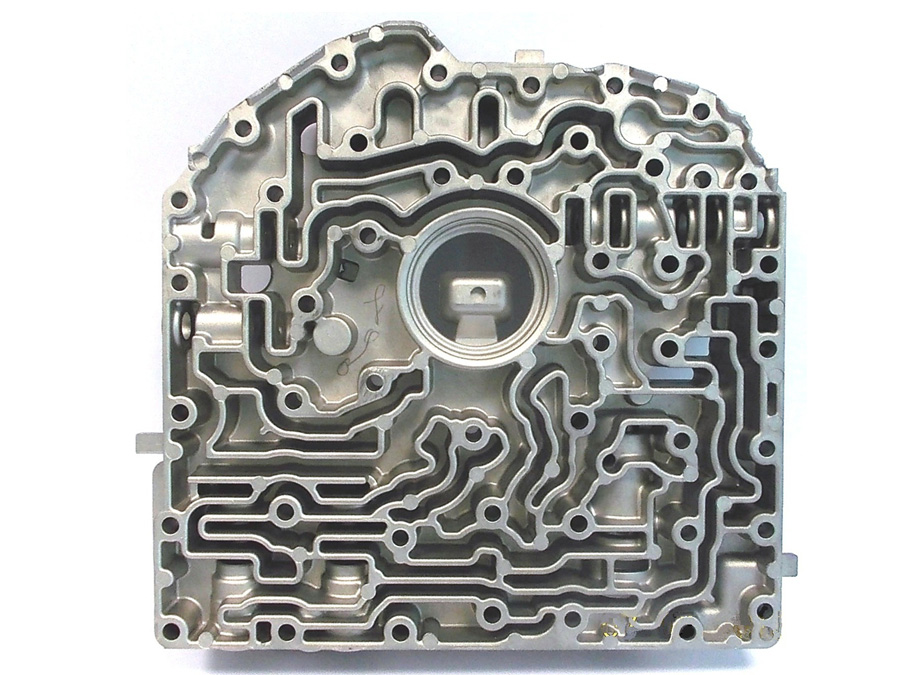

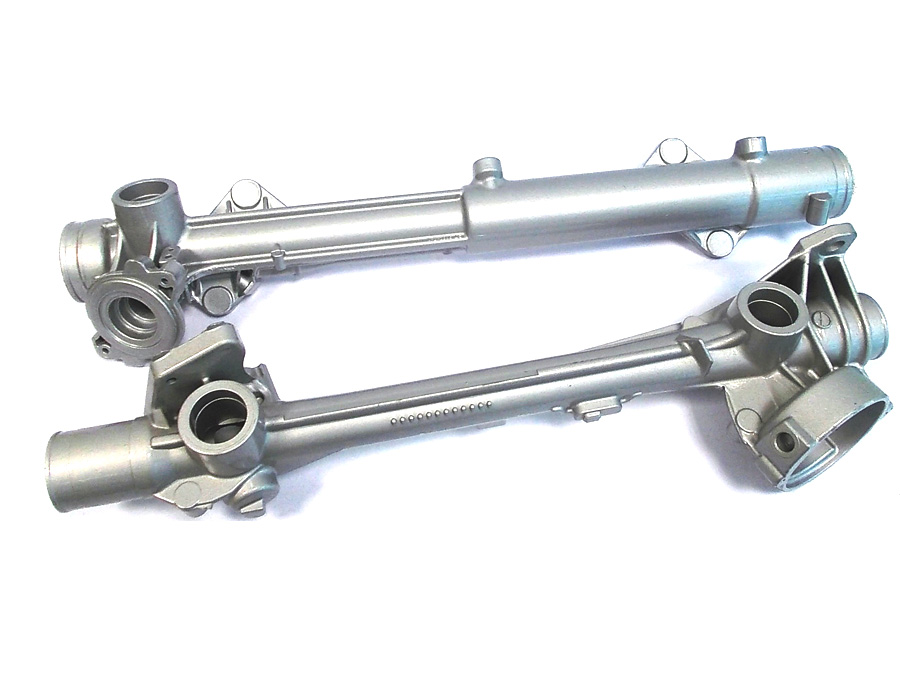

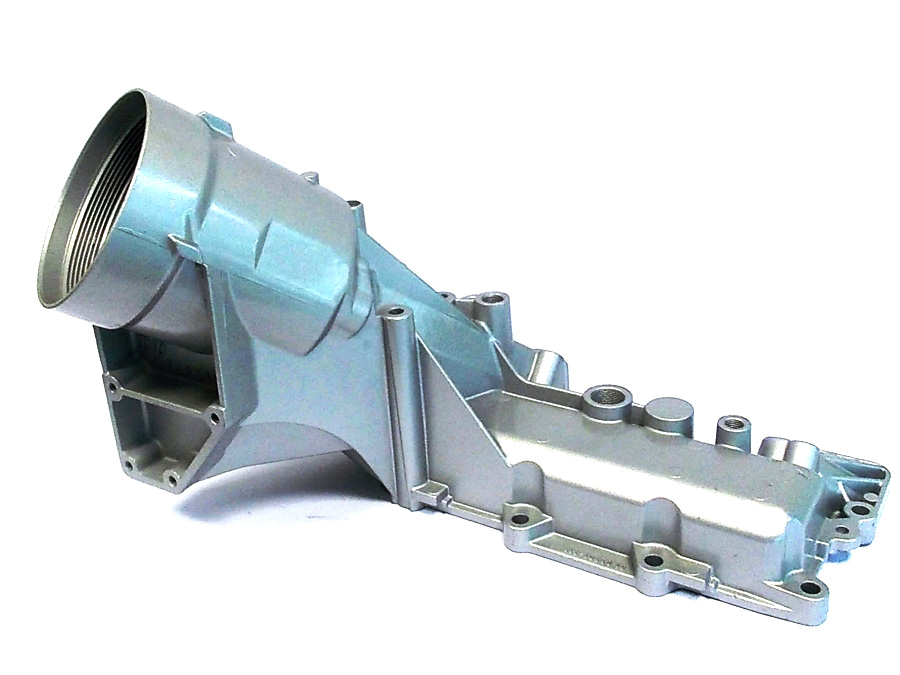

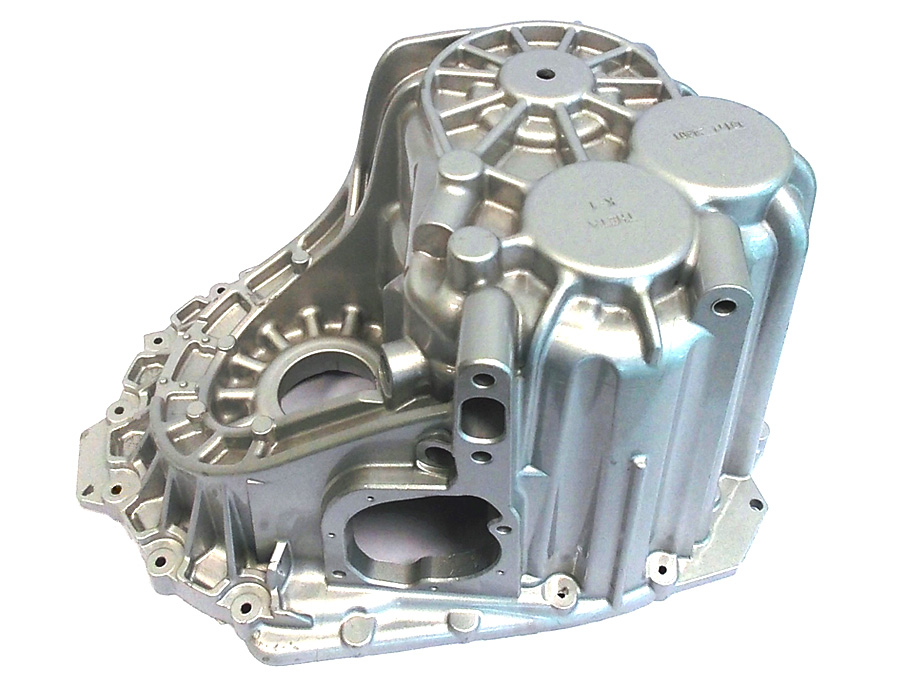

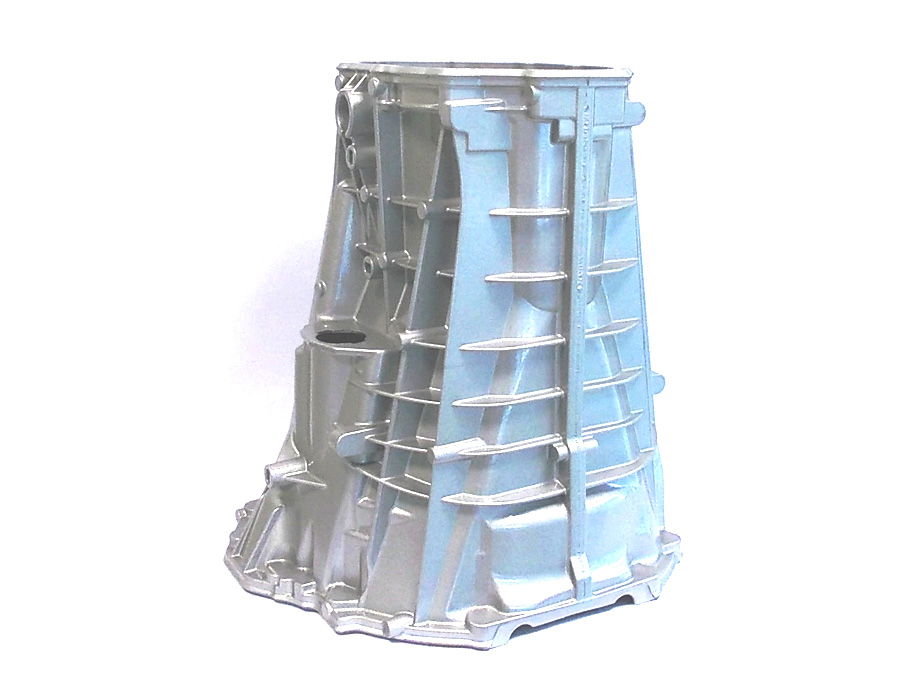

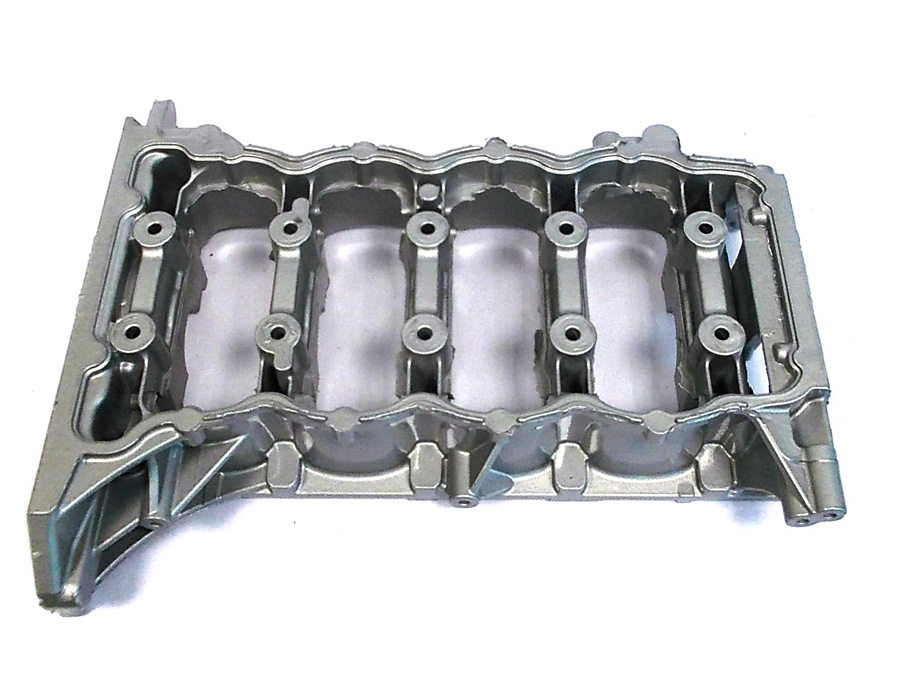

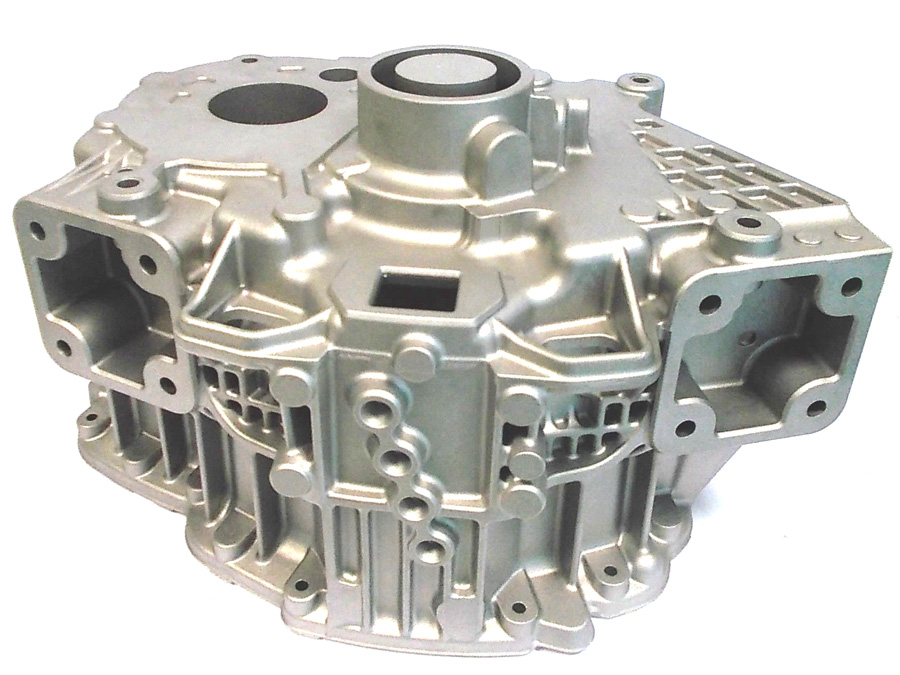

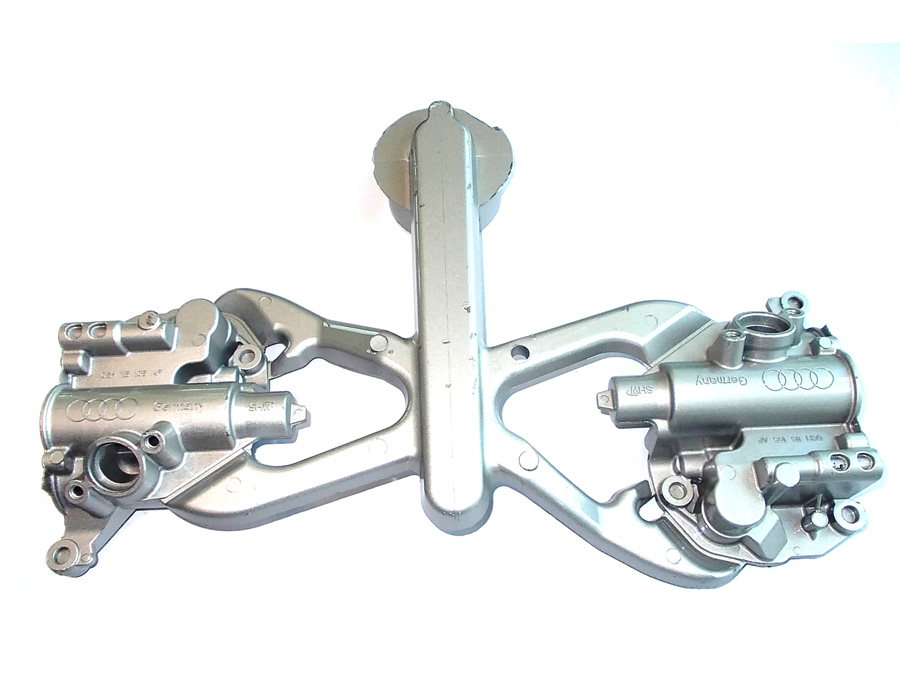

See Gallery

See gallery, here You’ll find some of our most significant products.

Production

Our

Production

See Gallery

See gallery, here You’ll find some of our most significant products.

Our strengths

Productive

Process

Messrs UNIVERSAL STAMPI designs and manufactures die casting dies for presses up to 3,500 tons of closing force and trimming tools for presses up to 50 tons.

The company can rely on its internal departments for Magmasoft® simulations, manufacturing of die frames, dimensional inspections, try-outs and pre-series productions.

Production Department

Working r20©

Try Outs and Pre-series Production

HPDC machines

Trimming Tools Department

Universal Mould

we give shape to your ideas

Company

©2020 Universal Stampi 4.0 S.r.l.

Via Giorgio la Pira, 13/23

25021- Bagnolo Mella (BS)

P.IVA: 04122250246

REA:BS - 577836

Cap.Soc: 1.600.000 €